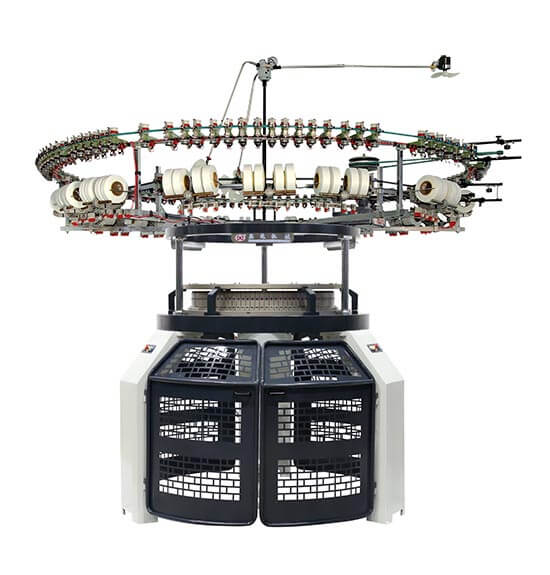

Single Jersey Circular Knitting Machine

Designed with the central adjustment system to adjust fabrics in different levels of density easily and conveniently, normally equipped with different gauges of cylinders which is easy to alter and can meet the varying requirements in the knitting market.

Main Features

Adopting the 4 track cams seal design and equipped with knit cams, tuck cams and miss cams. High precision central raising and falling system can adjust the fabric weight conveniently and quickly.

The special design of the feeding yarn carrier makes the option of Lycra more proficient. Featuring an ergonomic design, the additional middle feeding yarn transfer ring makes it easy for personnel to monitor and carry yarn, without the machine touching the operator’s body; at the same time, the yarn carrying system is freer and steadier, satisfying the demand of machine operating and knitting at high speeds.

Flexible for knitting varying fabrics and Multi-functional models.

A machine with multipurpose functions, by replacing the heart parts, it can easily converted into 3-thread-fleece and terry machine and other machines.

From single jersey knitting machine to 3-thread-fleece and terry machine

By changing a few parts, the machine can be configured to produce various different cloths, such as fiber covered cotton, single pique mesh, single fleece and small stripe cloth.

| Model | Cylinder Diameter | Machine Gauges | No. of Feeders | Speed |

|---|---|---|---|---|

| SJ3 | 16’’-44’’ | 16-36G | 3 F/Inch | 20-45 RPM |

| SJ4 | 26’’-44’’ | 18-30G | 4 F/Inch | 20-30 RPM |

| SJ6 | 26’’-44’’ | 20-30G | 6 F/Inch | 20-25 RPM |

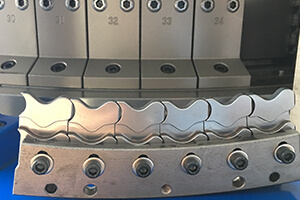

The Single Jersey Circular Knitting Machine parts perform dedicated, human hand-like knitting which adopts a 4-track cam seal design. A set of latch needles, cylinder and sinker ring all revolve along the stationary knitting cam systems.

The machine is equipped with knit cams, tuck cams and miss cams that variably controls the height of the needles and individual needle selection. High precision central raising and falling system can adjust the fabric weight conveniently and quickly.

Premium Quality Lycra can be made (For Spandex Manufacturing)

With our special design of the feeding yarn carrier, Lycra can be made as soft, elastic, flexible and more proficient than ever.

Featuring an ergonomic design, the additional middle feeding yarn transfer ring makes it easy for personnel to monitor and carry yarn, without the machine touching the operator’s body; at the same time, the yarn carrying system is freer and steadier, satisfying the demand of machine operating and knitting at high speeds.

Flexible for Knitting Varying Fabrics and Multi-functional Models

This conventional single jersey circular knitting machine can perform multi-purpose functions by just replacing the heart parts. Easy conversion into 3-thread-fleece and terry machine and other machines can be performed.