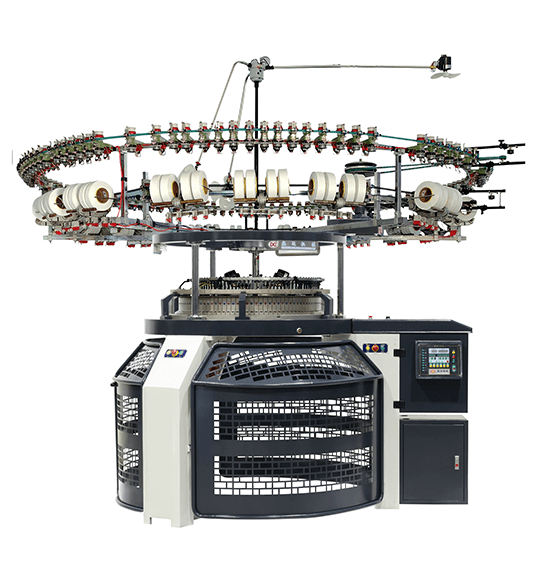

Single Terry Circular Knitting Machine

Featuring different types of sinkers, the terry single knitting machine is capable of knitting high-quality terry fabric of different loop height. With the Lycra attachment, it can also knit stretchy towel.

Main Features

Featuring different types of sinkers, the terry single knitting machine is capable of knitting high-quality terry fabric of different loop height. With the Lycra attachment, it can also knit stretchy towel. Moreover, velvet with protruding loops can be produced as this machine is characterized by reversed cams and normal cams.

Our Single Terry Circular Knitting Machine can be adjusted through the crimp and wheel tension based on the diverse fabric types and thickness required. We guarantee uniform cloth density and prevention of marks.

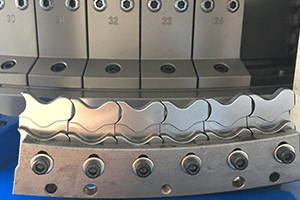

Each part, such as the motor,inverter, oiler, yarn storage device and yarn creel, is rigorously selected to ensure product quality is at premium. Cams are made of special alloy steel, CNC milled, grinded and heat treated. The needle track is also accurately made and runs smoothly, which ensures minimum part wear.

The unique design of CSA (Central Stitch Adjustment) makes adjustment of fabric density to be easy and accurate.

Flexible for knitting various fabrics and multi-functional models.

A machine with multi-purpose functions, by configuring specific parts, the machine can easily be converted into a 3-thread-fleece and plain single jersey 4-track circular knitting machine.

Stable Performance

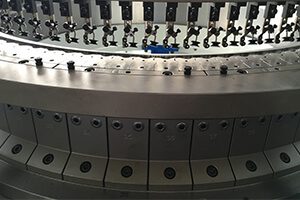

Groz-beckert Needles and Kern Sinkers are used to ensure fabric quality and long-life machine performance; cams are made of special alloy steel and processed by CNC and CAM treatment.

| Model | Cylinder Diameter | Machine Gauges | No. of Feeders | Speed |

|---|---|---|---|---|

| SJT | 26’’-34’’ | 18-24G | 2 F/Inch | 25 RPM |

Benefits:

Cloth Intricacy Maintained

We use a wire-race bearing exported from Germany that greatly enhances machine precision of up to 0.03mm tolerance.

Better Hand-Felt Terry Fabric Experience

The secret of producing high-quality terry fabric is the durability of the machine parts. All our machine parts are CNC machined and heat treated Cast Iron that will surely pass and exceed the test of time.

Long lifespan

Special processed cams and quality material insure higher utilization, less down time and long lifespan.